| Mechanical properties of C103 alloy at room temperature |

| Grade |

Composition (mass fraction)% |

Modulus of elasticity/MPa |

Tensile strength/MPa |

Yield strength/MPa |

Elongation/% |

| C-103 |

10Hf-1Ti-0.7Zr |

112490 |

428.9 |

259.3 |

20 |

|

| Thermal conductivity of C103 alloy (W/(m·℃)) |

| Grade |

800℃ |

1200℃ |

| C-103 |

37.4 |

42.4 |

|

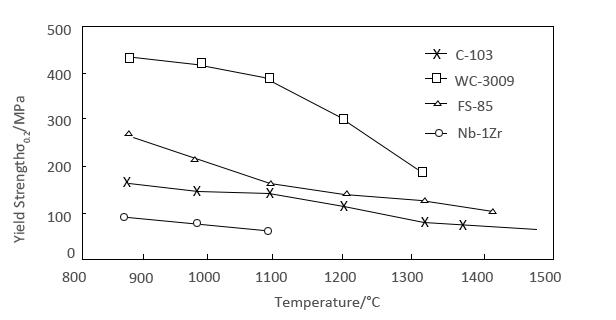

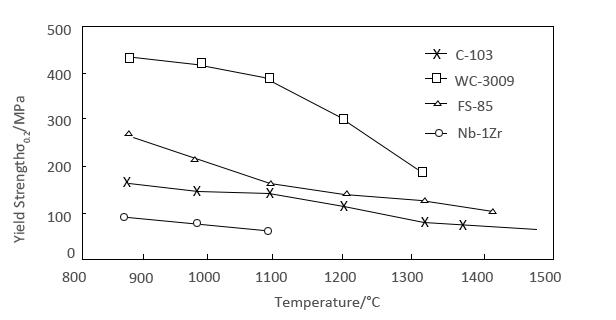

The yield strength curve of Niobium alloy with temperature rises

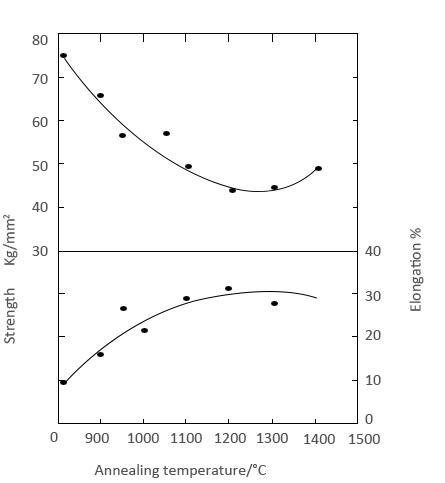

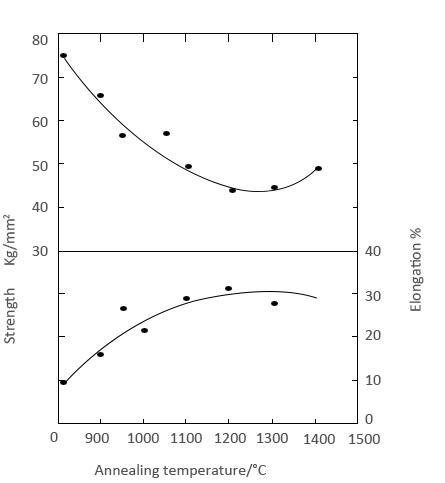

Effect of annealing temperature on properties of C103 Niobium alloy cold-rolled sheet

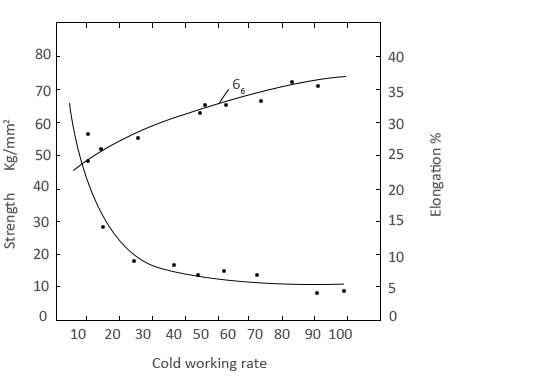

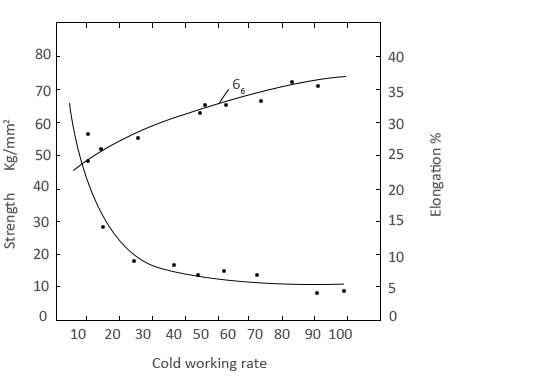

Effect of cold rolling rate on properties of C103 Niobium alloy sheet

Our C-103 products

If you have any inquiry for

C103 Plate/Sheet,

C103 Rod/

Wire,

C103 Tube,

C103 Parts and other kinds of products, welcome to contact our sales team.

All C-103 alloy components comply with ASTM B652, B654, AMS7852 and AMS7857 specifications. And if you have any special request, we can discuss about it.