Zirconium Tube / Pipe

Processing technology of Zirconium Tube / Pipe

The production processes of Zr-4 alloy tubes have adopted the key technologies as of beta treatment, control Q value and cumulative annealing parameter value, surface treatment and residual material recovery.

Compared with the production processes of Zr-2 alloy tube / pipe, a big step forward has been made.

Same processes are used to produce Zr-4 alloy square pipe, pure Zirconium composite pipe, Zr-2.5Nb alloy pressure pipe and Zr-2 alloy pressure pipe components.

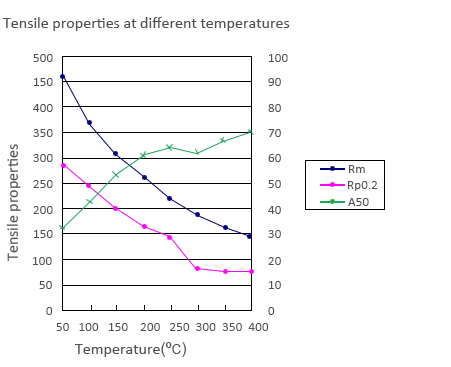

Properties of Zirconium Tube / Pipe

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tensile properties of industrial Zirconium Tubes at high temperature

Specifications and standard for Zirconium Tube / Pipe

|