Overview of Rhenium

Rhenium is the element with the highest melting point and boiling point in nature among chemical elements discovered by human beings. Its melting point is as high as 3,180 degrees Celsius, second only to Tungsten which is the most difficult melting in the nature.

Rhenium is very stable at high temperatures. It has the features of low vapor pressure, abrasion resistance, and resistance to arc corrosion, which make it a good self-cleaning contact material. Rhenium also has the properties of hardness, abrasion and corrosion resistance.

Rhenium has extremely high mechanical strength, A Rhenium alloy wire thinner than a hair is capable of withstanding more than 7kg of gravity.

Rhenium also has high electrical resistance and other electrical properties, with a resistivity of 3.84 times that of Tungsten and a modulus of elasticity similar to that of Iron.

Rhenium also has high electrical resistance and other electrical properties, with a resistivity of 3.84 times that of Tungsten and a modulus of elasticity similar to that of Iron.

Rhenium in the nature is composed of two isotopes, Re187 and Re185. Re187 is a radioactive isotope, accounting for 62.6% of natural Rhenium. Re185 is a non-radioactive isotope, accounting for 37.2% of natural Rhenium. With a half-life of 43 million a, Re187 emits very weak rays that cannot penetrate the skin and do no harm to human body.

Properties of Rhenium

|

||||||||||||

|

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||

Application of Rhenium

During the experiments, it was found that adding Rhenium to the Nickel alloy can significantly improve the creep strength of the superalloy and can also well resist deformation under long working time. Turbo engines can operate at higher temperatures with the engine blades made from Rhenium Nickel alloy. This means that the designers can improve the turbo ratio and thermal efficiency of the engine, so that the newly developed engine can have more thrust.

Tungsten-Rhenium alloy is composed of Tungsten matrix and different contents of Rhenium. Tungsten and Rhenium are both refractory metals. By fusion of the two components, with the effect of Rhenium, Tungsten-Rhenium alloy gets better ductility, higher recrystallization temperature, better creep resistance and higher resistivity than pure Tungsten. Tungsten-Rhenium alloy has good mechanical properties and can be machined and welded.

Due to its excellent high temperature properties, Tungsten-Rhenium alloy has different applications in parts and temperature measurement in high temperature environments that mainly include:

1. Aerospace: Tungsten-Rhenium alloy is applied to high-temperature components and temperature measurement system in aerospace field.

2. Semiconductor industry: due to its excellent physical properties, Tungsten-Rhenium alloy is used as high-temperature parts in equipment used in the semiconductor industry, such as heating devices and temperature measuring devices.

3. Industrial furnace: high temperature parts and temperature measuring device.

4. Welding industry: friction stir welding head.

1. Aerospace: Tungsten-Rhenium alloy is applied to high-temperature components and temperature measurement system in aerospace field.

2. Semiconductor industry: due to its excellent physical properties, Tungsten-Rhenium alloy is used as high-temperature parts in equipment used in the semiconductor industry, such as heating devices and temperature measuring devices.

3. Industrial furnace: high temperature parts and temperature measuring device.

4. Welding industry: friction stir welding head.

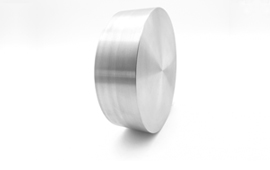

Our Rhenium products

We have Rhenium Pellet, Rhenium Rod, Rhenium Wire, Rhenium Crucible, Rhenium Target, Rhenium Tube and other Rhenium products