Processing technology of Ti-6Al-7Nb

1. Smelting process: select first-class sponge

Titanium, pure Aluminum, and Aluminum Niobium or Ti-Nb intermediate alloy as raw materials, mix according to nominal composition → press electrode → melt in secondary or tertiary vacuum consumable furnace to obtain qualified ingots with uniform composition, focusing on solving the uniformity of Niobium.

2. Heat treatment process: Ti-6Al-7Nb Titanium alloy is a rod alloy that is heat treated in an electric furnace. A simple annealing process is adopted to conduct heat treatment at 700℃/h with air cooling.

3.Deformation process and properties: Ti-6Al-7Nb belongs to α+β Titanium alloy, and its thermal processing process is similar to Ti-6Al-4V, and the heating temperature of general ingot is 1150 °C-1200 °C.

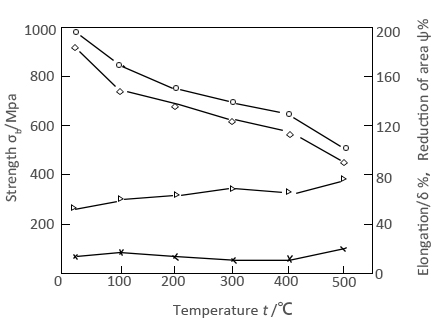

Through hot forging, precision forging and hot rolling, the alloy is made into rods with diameters of 110mm, 60mm, 30mm, 20mm and 12mm Ti-6Al-7Nb Rod, which can meet the tensile properties and other properties specified in the technical standards (ASTM F1295) at room temperature.

Also it can be made into Ti-6Al-7Nb Sheet for medical inplant use.