TB9

TB9 variety introduction

TB9 Titanium alloy (nominal composition of Ti-3Al-8V-6Cr4Mo-4Zr) is a metastable β Titanium alloy, molybdenum equivalent of about 19.6, can occur at 730° C α-β phase transition, after treatment can reach 1400MPa or more.It has the characteristics of low density, high strength, corrosion resistance, cold working and fatigue resistance, etc., and is often used to manufacture springs, petroleum gas pipeline control devices and various fasteners.

As a β-type Titanium alloy, TB9 Titanium alloy has good cold forming ability during processing, but the low deformation temperature often causes the microstructure of the alloy to be broken insufficiently, and the high deformation temperature is easy to cause the alloy to form coarse grains at high temperatures.

Therefore, in the production of TB9 and other β Titanium alloys, the appropriate rolling temperature is the first condition to ensure that the alloy bars obtain good microstructure and mechanical properties.

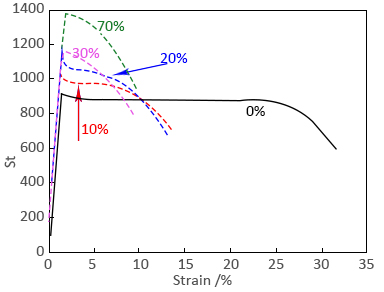

Rom temperature tensile properties of TB9 titanium alloy under different cold rotary-swaging rates

|

Note: Rp0.2-yield strength; Rm-tensile strength; A-elongation; Z-section shrinkage

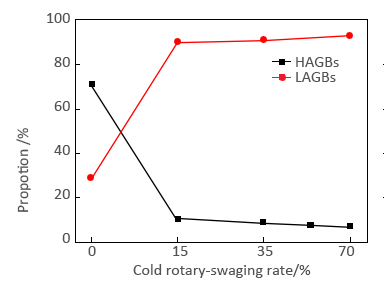

Proportion of HAGBs and LAGBs of the TB9 titanium alloy before and after cold rotary-swaging deformation

Room temperature tensile stress-strain curves of TB9 titanium alloy