TC11

TC11 variety introduction

The nominal composition of TC11 titanium alloy is Ti-6.5Al-3.5Mo-1.5Zr-0.3Si, which is a heat-resistant titanium alloy of α-β type, with an aluminum equivalent of 3.5 and a molybdenum equivalent of 7.3.

The alloy also has good thermal workability (including conventional process properties and superplasticity), and can be welded and machined in various ways.

The β heat treatment and isothermal forging of the alloy have been developed rapidly.

The alloy is also sensitive to thermal salt stress corrosion.

TC11 application

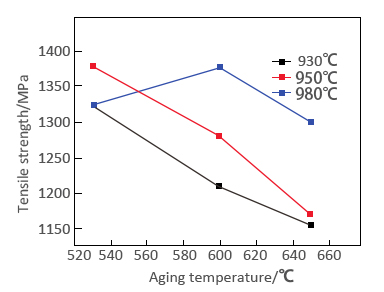

Tensile strength curves of TC11 Titanium alloy at different solution temperatures and aging temperatures

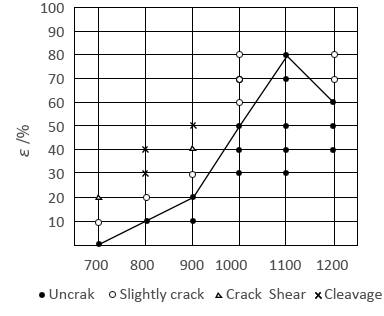

Plastic diagram of TC11 titanium alloy (as cast)