Monel K500

Overview of Monel K500

UNS N05500 (Monel K-500) is a nickel-copper alloy. It has the excellent corrosion resistance of UNS N04400 (Monel 400), as well as the advantages of higher strength and hardness.Higher performance is achieved by adding aluminium and titanium to the nickel-copper matrix and heating it under controlled conditions to precipitate submicroscopic Ni3(Ti, Al) particles throughout the matrix. The heat treatment used to affect precipitation is usually called age hardening or aging.

It has good heat and corrosion resistance as well as long-term microstructure stability.

It is mainly used for manufacturing turbine blades and gas turbine blades for aero engines with working temperatures below 750℃. Used for manufacturing fasteners and springs on ships; Pump and valve components on chemical equipment; Pulp scraping blades on papermaking equipment, etc.

One very practical property of this material is that it is non-magnetic and remains non-magnetic even at very low temperatures. However, it is also possible to form a magnetic film on the surface of the material during the processing. Heat treatment may selectively oxidize aluminium and copper, causing a magnetic nickel-based film to form on the material surface.

This property has a greater impact on fine wire and strip materials because their specific surface area accounts for a larger proportion. The magnetic film can be removed through acid washing or brightening processes, thus restoring the non-magnetic property of the material. K500 features non-magnetic properties, high strength and excellent corrosion resistance, and is thus widely used in oil well exploration equipment and electronic components.

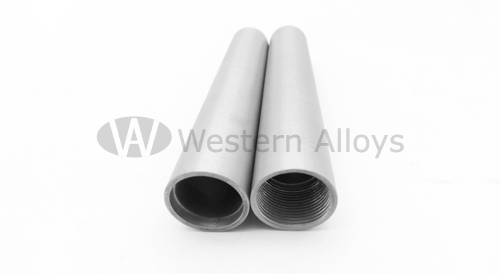

UNS N05500 alloy is available in tubes, thin plates, strips, plates, round bars, flat steel, forgings, hexagonal bars and wires.

Monel K-500 Composition

|

Monel K-500 Mechanical Properties

|