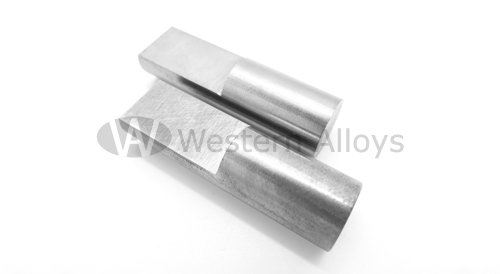

Hastelloy B-2

Overview of Hastelloy B-2

Hastelloy B-2 alloy is a Ni-Mo alloy with extremely low carbon and silicon contents. It reduces the precipitation of carbides and other phases in the weld seam and heat-affected zone, thereby ensuring good corrosion resistance even in the welded state.

Hastelloy B-2 alloy has excellent corrosion resistance in various reducing media and can withstand the corrosion of hydrochloric acid of any concentration at any temperature under normal pressure.

It has excellent corrosion resistance in medium concentration non-oxidizing sulfuric acid without aeration, various concentrations of phosphoric acid, high-temperature acetic acid, formic acid and other organic acids, bromic acid and hydrogen chloride gas.

Meanwhile, it is also resistant to the corrosion of halogen catalysts. Therefore, Hastelloy B-2 alloy is usually applied in a variety of harsh petroleum and chemical processes, such as the distillation and concentration of hydrochloric acid. In the production processes such as alkylation of ethylbenzene and low-pressure carbonylation synthesis of acetic acid.

The physical properties of Hastelloy B-2 alloy are as follows: Density: 9.24g/cm 3, melting point: 1330-1380℃, magnetic permeability: (℃, RT)≤1.001.

Hastelloy B-2 (UNS N10675) Chemical Composition

|

Hastelloy B-2 Special Properties

Excellent corrosion resistance to reducing environments

Excellent resistance to medium-concentration sulfuric acid and many non-oxidizing acids

Excellent resistance to all kinds of organic acid corrosion