Inconel 625

Overview of Inconel 625

Inconel 625 alloy is a solid-solution strengthened nickel-based deformable high-temperature alloy with molybdenum and niobium as the main strengthening elements.

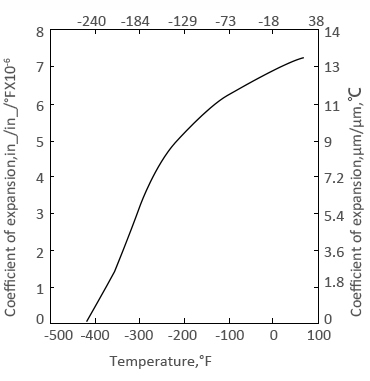

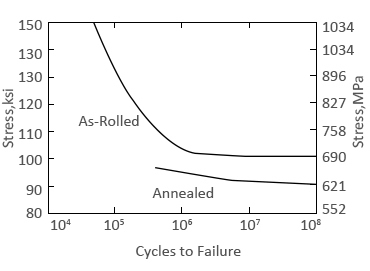

It features excellent corrosion and oxidation resistance, maintains good tensile and fatigue properties from low temperatures to 980℃, and is resistant to stress corrosion in salt spray atmospheres.

Inconel 625 alloy is designated as UNS N06625. Common standards include ASTM B366, ASTM B446, ASTM B443, ASTM B444, AMS5666, AMS5599, AMS5581.

Inconel 625 is usually used in the following forms: Inconel 625 welding wire, Inconel 625 bar and Inconel 625 plate.

Inconel 625 Properties

It has an extremely excellent corrosion resistance to various corrosive media in both oxidizing and reducing environments

It has excellent resistance to pitting corrosion and crevice corrosion, and will not cause stress corrosion cracking due to chlorides

Excellent resistance to inorganic acids, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid, and mixed acids of sulfuric acid and hydrochloric acid, etc

It has excellent resistance to pitting corrosion and crevice corrosion, and will not cause stress corrosion cracking due to chlorides

Excellent resistance to inorganic acids, such as nitric acid, phosphoric acid, sulfuric acid, hydrochloric acid, and mixed acids of sulfuric acid and hydrochloric acid, etc

Excellent resistance to corrosion from various inorganic acid mixed solutions

When the temperature reaches 40℃, it can exhibit excellent corrosion resistance in hydrochloric acid solutions of various concentrations

Good processability and weldability, with no sensitivity to cracking after welding

It has manufacturing certification for pressure vessels with wall temperatures ranging from -196 to 450℃

When the temperature reaches 40℃, it can exhibit excellent corrosion resistance in hydrochloric acid solutions of various concentrations

Good processability and weldability, with no sensitivity to cracking after welding

It has manufacturing certification for pressure vessels with wall temperatures ranging from -196 to 450℃

Inconel 625 Application

The main development target of Inconel 625 alloy is for use in steam pipelines. It has also been widely used in aero engines as well as pulp and paper equipment.

The main application scope of alloy Inconel 625 is: thermal protection, furnace modules, aviation and onshore gas turbine engines, combustion bushings, chemical processing plants, offshore seawater applications.

Such as sheaths for underwater communication cables, pollution control and nuclear power reactors, jet engines, flue gas scrubbers, acidic gas production pipelines and chimney linings.

Due to its highest strength among nickel alloys, Inconel 625 is widely used in the manufacture of aviation engineering components, such as steel wire ropes, propeller blades and propulsion motors.

The main application scope of alloy Inconel 625 is: thermal protection, furnace modules, aviation and onshore gas turbine engines, combustion bushings, chemical processing plants, offshore seawater applications.

Such as sheaths for underwater communication cables, pollution control and nuclear power reactors, jet engines, flue gas scrubbers, acidic gas production pipelines and chimney linings.

Due to its highest strength among nickel alloys, Inconel 625 is widely used in the manufacture of aviation engineering components, such as steel wire ropes, propeller blades and propulsion motors.