Inconel 600

Overview of Inconel 600

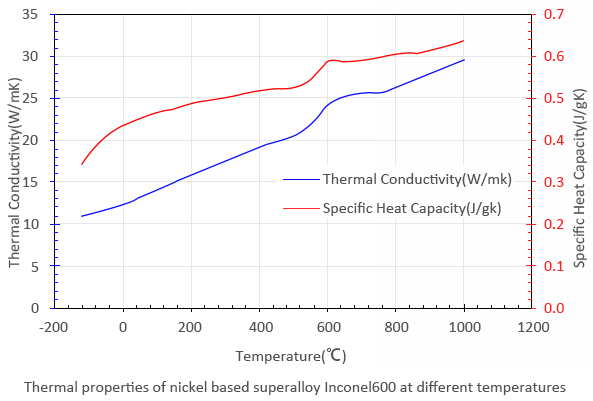

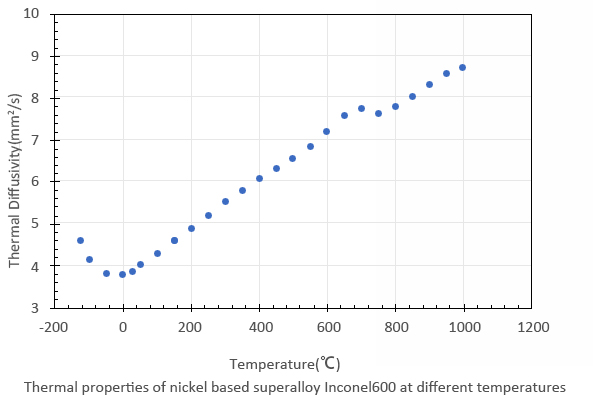

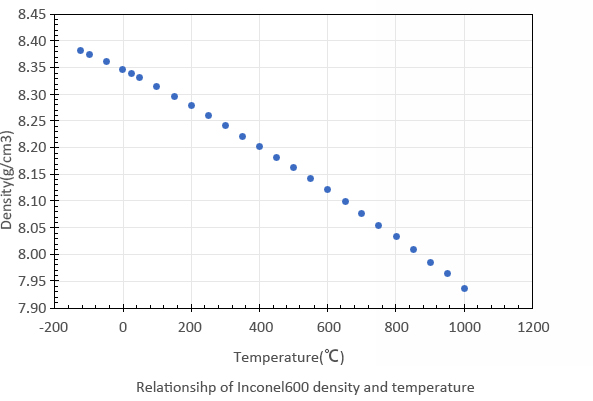

Inconel 600 alloy is nickel-chromium-iron based solid solution strengthened alloy, the alloy has good high temperature corrosion resistance and oxidation resistance, excellent hot and cold processing and welding performance.It has met the heat strength and high plasticity below 700℃.

The alloy can be strengthened by cold working and can also be joined by resistance welding, soldering or brazing, making it suitable for the manufacture of oxidation resistant parts under low loads up to 1100℃.

Inconel 600 Chemical Element Content (%)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Inconel 600 Process Functions and Requirements

1. This alloy has outstanding thermal processing function, ingot forging heating temperature 1110℃ ~ 1140℃.

2. The uniform grain size of the alloy is closely related to the deformation degree of the forging and the final forging temperature.

3. The alloy has excellent welding function, which can be connected by various methods such as raw arc welding, argon arc welding, resistance welding and brazing.

Large or messy welded structural parts should be annealed at 870℃ for 1h after soldering to eliminate welding stress.

Large or messy welded structural parts should be annealed at 870℃ for 1h after soldering to eliminate welding stress.

4. The alloy must be machined after heat treatment, because of the work hardening of the material, it is appropriate to use a lower cutting speed and heavy feed than the processing of low-alloy standard austenitic stainless steel, so that the car can be driven under the cold hardened surface.