Zr-4 Tube / Zr-4 Bar

Production of Zr-4 Tube and Zr-4 Bar

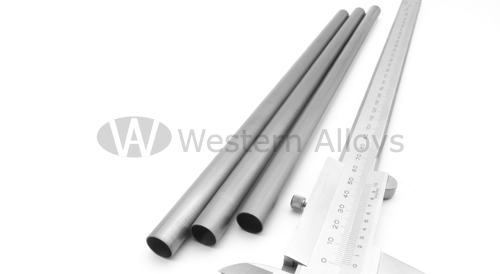

To obtain the desired surface quality, cold rolling process is usually used in the production of Zr-4 Tubes rather than drawing process.

For cladding tube of the nuclear fuel elements, due to the high consumption and strict standard, two-roll or multi-roll cold rolling are usually used.

The size range of Zirconium alloy cladding tube for PWR is φ6 ~ 15mm × wall thickness 0.4 ~ 0.7mm. Zr-4 Rods for fuel element end plugs are normally produced through extruding the rods and forging them by cold rotation instead of cold drawing process.

Application of Zr-4 Tube and Zr-4 Bar

Zr-4 alloy has excellent nuclear and structural properties. It is widely used as a structural material in nuclear reactors, and Zr-4 Tube is mainly used as the cladding material of nuclear fuel.

Zr-4 Rods are mainly used for fuel element end plugs.

Our Zr-4 Tube and Zr-4 Bar products

Zr-4 Tube follows ASTM B353 R60804, Zr-4 Rod follows ASTM B351 R60804.

|

|||||||||||